In this blog series, I attempt to list some KPIs which may help to evaluate your SAP supply chain. I realize that there are many key figures, KPIs, characteristics and measures available in the general supply chain area. Many are a bit confusing and it is sometimes hard to pick the right ones out of all the various options. Here I want to discuss some of those that I deem very important and helpful.

Let me start out with what I would like to call the Service Rating. Some call it Service Level others Service Grade and in MTS it's also called Fill Rate. In the end it's a measure which informs about how well a source or a supply delivers to a consumer or customer. I often see this indicator applied only in Sales; how good are we delivering product to our customer!?

But in a supply chain there are many sources, suppliers, customers or consumers. A production line may be the supplier to the warehouse. The production line in turn, might be the consumer to a work center making fabricated parts. Or the external vendor can be the source to that work center - which now becomes the customer.

In that sense we can rate the service for every supplier - customer (source - consumer) relationship separately. To further this thought, I'd like to list the possible Service Ratings in a supply chain as follows:

- supplier to purchased parts (raw materials) orders: This indicates how well your individual suppliers perform to orders they receive from your buyers.

- purchased parts (raw materials) warehouse to production (lines or work centers). This measures how well your purchasing department performs to supply your production.

- fabrication of semi-finished products to assembly, measures production-internal performance.

- final assembly (finished goods production) to warehouses and distribution centers for sellable products. A rating on how well the production schedulers perform to forecast and planning.

- warehouse and distribution center to customer. Here we can tell how good the forecast and planning was executed.

Each one of these Service Ratings should be measured as a percentage and everytime a request could not be fulfilled the rating should degrade. You can measure this either by quantity or on time but don't forget that if any given source (supplier) "cheats" by putting up excessive inventories, they will get good ratings. But these are, of course, very costly.

You should therefore always relate the Service Rating with the Inventory Holding.

As an example: if you sent a forecast for 100 pieces to your production scheduler and they delivered 97 on time; the schedulers had achieved a service rating of 97%. The next question you then need to ask is how much resources did they consume to achieve this rating. Overtime? Extra capacity? What was the yield from the line? Waste? Etc.

These are different KPI's but they must be considered if you want to really know how good your Service Ratings are.

SAP Mentor, supply chain management enthusiast. Advocate for science as a basis to optimize the SAP supply chain. Active in Europe and North America. Sailboater, private pilot, motorbiker. At home in Tribeca, NYC. The opinions expressed in this blog are mine!

Wednesday, September 26, 2012

Tuesday, September 25, 2012

10 things to watch out for when they come to optimize your SAP supplychain. Part 3 - the last three

...when it comes to SAP supply chain optimizations, I am getting a little excited... but I don't get arrogant. I believe I know a lot about SAP transactions and what you can do in MM, PP, SD and CO. However, I would never walk into your company and tell everybody there, that what they do is wrong.

There are consultants that make a living with that statement and they intimidate their clients with their 'superior' knowledge of SAP transactions and how these should drive someones business. But you don't run a company with SAP transactions. Those are supporting tools that may save a lot of work and bring automation and provide visibility, however, if you would do everything wrong, then you wouldn't be in business in the first place and my question is: why does that consulting company not run a business like yours? when they know so much better how to run your business?

Beware of business improvers... get an SAP supply chain optimizer to optimize your SAP supply chain workings and not a business theory guru who never ran a company in his life (in some cases never worked in an SAP system either - isn't it amazing how these people get by undetected?)

We SAP consultants need to help you with your SAP supply chain and clearly lay out the options you have available with the software you aquired for so much money. These options are the replenishment, planning and scheduling policies one can configure and setup in SAP, so that they support and help to automate the business processes which have worked well for you over the years.

so... Eigth: "An SAP supply chain optimizer enables your user to execute your existing business process more efficient and in an automated, time and cost saving fashion - they do NOT change the way you are doing business (Thank God!)".

Ninth: "Your user needs coaching, not schooling"

There is no doubt in my mind that every Person using SAP needs continuous education on the subject. It is too complex of a system to ever know everything about it.

Where I differ in my opinion with some consultants is how that education should be done. A training class with slides is good for the SAP novice but not for someone who knows some things well and other things not at all. How does that trainer, with his/her standard slide deck, know what the experienced user knows by now and what they need help with? Therefore a 'canned' training class is not very effective.

What I believe works very well is 'coaching'. A coach shows empathy and puts himself into his subjects shoes. In football a coach works with the team as well as with the individual. So it should be in the SAP supply chain. We need more coaches who can make a supply chain team work in harmony (to fight the bullwhip effect) and guide the individual (planners, buyers, schedulers) to supply chain excellence, caring for the individual's need for education.

In my mind that kind of thing can not be achieved with a bunch of 'methodic' training classes and a subsequent testing program where everybody gets a certificate to pin up on the wall. By the way: testing people is for the Department of Motor Vehicles when they ensure that everybody has basic driving skills. Michael Schumacher and Sebastian Vettel didn't get to be exceptional through certification; they got there with a lot of help from coaches. And it usually does not work that well when you try to build a positive environment that is conducive to empowering the user. Especially when some users fail the test - who knows why? Bad question, nervousness, questions unrelated to their job, confusing or mediocre teaching beforehand? - and subsequently have to fear for their job security and therefore: their livelihood (be careful teaching consultant; about what you are doing with other peoples lives!).

Get a coach who can listen and help, not a teacher who shows up to tell you how things are done... and then does like a tree and leaves.

And Tenth: "a rigid methodology does not work for an optimization"

What's absolutely disturbing to me is how some optimizers go out there with their methodology in their bag and then they walk through your door and say: "here is what we're going to do..." ( ok, they might spend a few days pretending to understand your SAP setup - and maybe even your business - in a so-called assessment that they charge an arm and a leg for).

Then they pull out a powerpoint presentation and talk about how you "need" to change your course of action. Here is a guy who has never stood by a production line; and he talks about how you should "value stream map your heijunka pull". Nice graphics too...

Don't sign up for an optimization based on buzz words. Get them to show you measurable results. Don't sign up for a three months project to optimize your supply chain. What kind of an optimization is that? It can't be done in that time and all it means is that the consultant wants an "in" so you have no "out" later.

Here is my suggestion: when they come knocking at your door, give them a chance and let them do an assessment - for free! (They want your business, right?). Then have them propose an action, not a project but an action, to achieve measurable results. Measurable results with a clear path on how to reach them.

As an example: if I were to see your SAP supply chain, I would focus on three things:

1. How do you, as a company, bring in and store purchased parts and raw materials.

2. How do you, as a company, plan for and store sellable products.

3. How do you, as a company, use the information provided above, to schedule your production

These are the three areas where you can use SAP software to optimize and automate your business and if they are not part of the pitch, you might as well ask for your time back.

Should your optimization partner talk about how they get you Process Performance (is that measured in kilograms?), Information Maturity (is there information adolescence and how should we grow up?) or come with shady suggestions to apply 'proven techniques to balance supply with demand', then you know it's shallow talk and you're in for an expensive, worthless ride.

On the other hand; if the SAP partner engages in an effort to measure where you stand in terms of replenishment, planning and scheduling strategies and, on top of that, paves the way on how you get your users educated on how to set and use the right policies in SAP - you got a worthwhile exercise to pursue. Especially if the offer includes a coaching program which ensures sustainability.

This is not a forum to promote certain consulting companys over others, however, if I may make one suggestion then it would involve Marc Hoppe, author, consultant extraordinair and head of SAP Consulting's optimization unit.

Have a read of his books. I strongly suggest these when you want to optimize your SAP supply chain - whether you hire consultants or you do it yourself.

There are consultants that make a living with that statement and they intimidate their clients with their 'superior' knowledge of SAP transactions and how these should drive someones business. But you don't run a company with SAP transactions. Those are supporting tools that may save a lot of work and bring automation and provide visibility, however, if you would do everything wrong, then you wouldn't be in business in the first place and my question is: why does that consulting company not run a business like yours? when they know so much better how to run your business?

Beware of business improvers... get an SAP supply chain optimizer to optimize your SAP supply chain workings and not a business theory guru who never ran a company in his life (in some cases never worked in an SAP system either - isn't it amazing how these people get by undetected?)

We SAP consultants need to help you with your SAP supply chain and clearly lay out the options you have available with the software you aquired for so much money. These options are the replenishment, planning and scheduling policies one can configure and setup in SAP, so that they support and help to automate the business processes which have worked well for you over the years.

so... Eigth: "An SAP supply chain optimizer enables your user to execute your existing business process more efficient and in an automated, time and cost saving fashion - they do NOT change the way you are doing business (Thank God!)".

Ninth: "Your user needs coaching, not schooling"

There is no doubt in my mind that every Person using SAP needs continuous education on the subject. It is too complex of a system to ever know everything about it.

Where I differ in my opinion with some consultants is how that education should be done. A training class with slides is good for the SAP novice but not for someone who knows some things well and other things not at all. How does that trainer, with his/her standard slide deck, know what the experienced user knows by now and what they need help with? Therefore a 'canned' training class is not very effective.

What I believe works very well is 'coaching'. A coach shows empathy and puts himself into his subjects shoes. In football a coach works with the team as well as with the individual. So it should be in the SAP supply chain. We need more coaches who can make a supply chain team work in harmony (to fight the bullwhip effect) and guide the individual (planners, buyers, schedulers) to supply chain excellence, caring for the individual's need for education.

In my mind that kind of thing can not be achieved with a bunch of 'methodic' training classes and a subsequent testing program where everybody gets a certificate to pin up on the wall. By the way: testing people is for the Department of Motor Vehicles when they ensure that everybody has basic driving skills. Michael Schumacher and Sebastian Vettel didn't get to be exceptional through certification; they got there with a lot of help from coaches. And it usually does not work that well when you try to build a positive environment that is conducive to empowering the user. Especially when some users fail the test - who knows why? Bad question, nervousness, questions unrelated to their job, confusing or mediocre teaching beforehand? - and subsequently have to fear for their job security and therefore: their livelihood (be careful teaching consultant; about what you are doing with other peoples lives!).

Get a coach who can listen and help, not a teacher who shows up to tell you how things are done... and then does like a tree and leaves.

And Tenth: "a rigid methodology does not work for an optimization"

What's absolutely disturbing to me is how some optimizers go out there with their methodology in their bag and then they walk through your door and say: "here is what we're going to do..." ( ok, they might spend a few days pretending to understand your SAP setup - and maybe even your business - in a so-called assessment that they charge an arm and a leg for).

Then they pull out a powerpoint presentation and talk about how you "need" to change your course of action. Here is a guy who has never stood by a production line; and he talks about how you should "value stream map your heijunka pull". Nice graphics too...

Don't sign up for an optimization based on buzz words. Get them to show you measurable results. Don't sign up for a three months project to optimize your supply chain. What kind of an optimization is that? It can't be done in that time and all it means is that the consultant wants an "in" so you have no "out" later.

Here is my suggestion: when they come knocking at your door, give them a chance and let them do an assessment - for free! (They want your business, right?). Then have them propose an action, not a project but an action, to achieve measurable results. Measurable results with a clear path on how to reach them.

As an example: if I were to see your SAP supply chain, I would focus on three things:

1. How do you, as a company, bring in and store purchased parts and raw materials.

2. How do you, as a company, plan for and store sellable products.

3. How do you, as a company, use the information provided above, to schedule your production

These are the three areas where you can use SAP software to optimize and automate your business and if they are not part of the pitch, you might as well ask for your time back.

Should your optimization partner talk about how they get you Process Performance (is that measured in kilograms?), Information Maturity (is there information adolescence and how should we grow up?) or come with shady suggestions to apply 'proven techniques to balance supply with demand', then you know it's shallow talk and you're in for an expensive, worthless ride.

On the other hand; if the SAP partner engages in an effort to measure where you stand in terms of replenishment, planning and scheduling strategies and, on top of that, paves the way on how you get your users educated on how to set and use the right policies in SAP - you got a worthwhile exercise to pursue. Especially if the offer includes a coaching program which ensures sustainability.

This is not a forum to promote certain consulting companys over others, however, if I may make one suggestion then it would involve Marc Hoppe, author, consultant extraordinair and head of SAP Consulting's optimization unit.

Have a read of his books. I strongly suggest these when you want to optimize your SAP supply chain - whether you hire consultants or you do it yourself.

Sunday, September 23, 2012

10 things to watch out for when they come to optimize your SAP supply chain. Part 2 - the next three

...on we go. SAP supply chain optimization without getting ripped off.

Fifth: "A good talk: nice; actual experience: priceless". Have you ever sat through a presentation and then you felt like... 'What was that all about?' Might have been someone talking about a subject they never actually experienced. It is amazing to me how some people who never worked for a manufacturing company think they can all of a sudden give advice on how you should map out your value stream or use heijunka! (It's like a fat guy telling the pretty girl how to loose weight)

Yes, they know all the buzzwords and they make great use of it - value streams, the perfect plant, lean operations, heijunka, etc. - and then they are unable to explain the Kanban principle (the most simple there is). It is because they might have read a lot of literature but they have never experienced it themselves. You can read as much as you want about American Football and after a while you probably even do a presentation on it and talk at a conference about what offense, defense and special teams you will put on the field, but when it comes to that third down in the fourth quarter, with a minute to go... not in a million years would I take your advice, hadn't you ever played on a football team. It doesn't matter if that experience comes from a professional level or from a junior high school team. It's the actual experience, of seeing it in action, that counts. (that's why some of the best coaches have never played in the NFL).

Sixth: "not everything can be done using SAP - ERP standard"... there are things SAP standard just can't do. That is why SAP signs up partners with add-on tools and enhancements to cover white spots in the SAP functionality. If you try, at all cost, to do everything with standard SAP, you will end up with missing functions (lot size simulation, safety stock optimization), missing information (XYZ or LMN or EFG analysis and essential key figures) and, in case you're doing inventory analysis with the LIS; with graphs, reports and technology that was exciting during the late '80s.

Don't let an adviser tell you to not ever look into SAP certified Add-Ons or one of these really helpful tools to make your user's life easier and provide them with the functionality to continuously and sustainably optimize inventories and service levels. When they claim: "SAP functionality is all you ever need", then they have probably never experienced an optimized supply chain themselves and only see implementations. During an implementation you are constrained by budget, timelines and your users are still overwhelmed with all the functions available in standard SAP and how to make them work. However, if you are ready to go above and beyond basic supply chain management with SAP, you will need an XYZ analysis, a useful and technologically advanced KPI framework, and, Advanced Planning and Optimization (the adviser told you to not use APO either, right? trust me, it's because they don't know it)

I mentioned some of these enhancements in previous blogs and strongly suggest to have a closer look.

Seventh: "supply chain optimizations don't work with 'silo' subject matter knowledge alone". Don't they tell you to break down silos? And then they work inside them too! Many consultants are focusing on a single piece of the SAP software. Like 'Procurement' or 'Inventory Management'. They usually know a lot about that subject and they probably also know direct interfaces into the other modules, but I don't believe that that is enough. Especially in supply chain management and optimization you should have deep knowledge in ALL areas since the impacts are severe.

As an example... I have witnessed advisers coming in to suggest an inventory reduction first and once that is done, they worry about production scheduling. If you reduce your purchased parts inventory based on some information like high dead stock, high averages or inventory turns alone, you are doomed to starve the lines and everything your production schedulers try to save the world, will fail and frustrate the hell out of them.

Check on the multi-functional knowledge of the consulting company. If they are talking on and on about Procurement and Inventory reductions, ask them about the effects of an inventory reduction and how Purchasing Automation can possibly help keeping your lines busy with the making of the right product in the right quantity at the right time.

Some others put a huge focus on Sales & Operations Planning and keeping an accurate forecast (btw... 'accurate forecast' is an oxymoron). That is all great, but if they don't worry about what happens after the plan is in place (demand smoothing for the production line, MTO vs. MTS setup and the according measure of the service level, procurement forecast for the purchasing of the needed raw materials and use of the appropriate scheduling model), you're not providing a solution or solve any problems.

Planning is not a stand alone activity; neither is procurement or inventory reduction. Make sure you are working with consultants who know that.

... the last three bits out of ten in a little while.

Fifth: "A good talk: nice; actual experience: priceless". Have you ever sat through a presentation and then you felt like... 'What was that all about?' Might have been someone talking about a subject they never actually experienced. It is amazing to me how some people who never worked for a manufacturing company think they can all of a sudden give advice on how you should map out your value stream or use heijunka! (It's like a fat guy telling the pretty girl how to loose weight)

Yes, they know all the buzzwords and they make great use of it - value streams, the perfect plant, lean operations, heijunka, etc. - and then they are unable to explain the Kanban principle (the most simple there is). It is because they might have read a lot of literature but they have never experienced it themselves. You can read as much as you want about American Football and after a while you probably even do a presentation on it and talk at a conference about what offense, defense and special teams you will put on the field, but when it comes to that third down in the fourth quarter, with a minute to go... not in a million years would I take your advice, hadn't you ever played on a football team. It doesn't matter if that experience comes from a professional level or from a junior high school team. It's the actual experience, of seeing it in action, that counts. (that's why some of the best coaches have never played in the NFL).

Sixth: "not everything can be done using SAP - ERP standard"... there are things SAP standard just can't do. That is why SAP signs up partners with add-on tools and enhancements to cover white spots in the SAP functionality. If you try, at all cost, to do everything with standard SAP, you will end up with missing functions (lot size simulation, safety stock optimization), missing information (XYZ or LMN or EFG analysis and essential key figures) and, in case you're doing inventory analysis with the LIS; with graphs, reports and technology that was exciting during the late '80s.

Don't let an adviser tell you to not ever look into SAP certified Add-Ons or one of these really helpful tools to make your user's life easier and provide them with the functionality to continuously and sustainably optimize inventories and service levels. When they claim: "SAP functionality is all you ever need", then they have probably never experienced an optimized supply chain themselves and only see implementations. During an implementation you are constrained by budget, timelines and your users are still overwhelmed with all the functions available in standard SAP and how to make them work. However, if you are ready to go above and beyond basic supply chain management with SAP, you will need an XYZ analysis, a useful and technologically advanced KPI framework, and, Advanced Planning and Optimization (the adviser told you to not use APO either, right? trust me, it's because they don't know it)

I mentioned some of these enhancements in previous blogs and strongly suggest to have a closer look.

Seventh: "supply chain optimizations don't work with 'silo' subject matter knowledge alone". Don't they tell you to break down silos? And then they work inside them too! Many consultants are focusing on a single piece of the SAP software. Like 'Procurement' or 'Inventory Management'. They usually know a lot about that subject and they probably also know direct interfaces into the other modules, but I don't believe that that is enough. Especially in supply chain management and optimization you should have deep knowledge in ALL areas since the impacts are severe.

As an example... I have witnessed advisers coming in to suggest an inventory reduction first and once that is done, they worry about production scheduling. If you reduce your purchased parts inventory based on some information like high dead stock, high averages or inventory turns alone, you are doomed to starve the lines and everything your production schedulers try to save the world, will fail and frustrate the hell out of them.

Check on the multi-functional knowledge of the consulting company. If they are talking on and on about Procurement and Inventory reductions, ask them about the effects of an inventory reduction and how Purchasing Automation can possibly help keeping your lines busy with the making of the right product in the right quantity at the right time.

Some others put a huge focus on Sales & Operations Planning and keeping an accurate forecast (btw... 'accurate forecast' is an oxymoron). That is all great, but if they don't worry about what happens after the plan is in place (demand smoothing for the production line, MTO vs. MTS setup and the according measure of the service level, procurement forecast for the purchasing of the needed raw materials and use of the appropriate scheduling model), you're not providing a solution or solve any problems.

Planning is not a stand alone activity; neither is procurement or inventory reduction. Make sure you are working with consultants who know that.

... the last three bits out of ten in a little while.

Thursday, September 20, 2012

10 things to watch out for when they come to optimize your SAP supply chain. Part 1 - the first four

You probably heard it many times over: "we will reduce your inventory by 30%" (when? which inventory? why?), "we show you things in SAP you have never seen before" ( that's great, but what is the value in that?).. "Don't ever use an add-on. These are bad" (really? Is that a rule?); "...the way to better business is by Information Maturity" (has there ever been a more useless slogan?) or "safety stock can lead to excess or insufficient stock(duh). We show you how to solve that problem with exception management" (oh boy! Are you trying to tell me that I should reduce variability in MD06??).

Too vague in my mind. And they're all selling tools... which are supposed to get you sign off on an optimization project that might cost you a lot of money without getting much, or anything out of it.

I truly do believe you should constantly improve and optimize your SAP supply chain but beware of the Sharlatans and "thought leading" experts who do a good talk but never show up when the rubber hits the road.

Here are the first four of ten bits, I think you should watch out for when the people who halfheartedly reveal all the opportunities and promise ongoing value, show up at your door knocking.

First: "only the very best advisors will do!" Most SAP consultants get away with not knowing much during the implementation. As long as they know a little bit more than the user (who, at that time usually knows only little or nothing about SAP), they look credible and knowledgeable. But once your buyers and planners were exposed to the workings of the system for years and are experiencing severe pain and developed their own work-arounds - it will take a very, very experienced and solution oriented consultant who is a top notch communicator to get your team back on track.

Be very careful and get to know the people who will perform the actual work with your team and don't let the consulting company fool you with their best few during the assessment. Very often the consulting company comes in with a "thought leader" who speaks big words and does his 'Spiel', only to leave you with a team that is inexperienced and overwhelmed with the task at hand. It also does not take a horde of consultants to do the job right. If they give you one for Purchasing and another one for Forecasting, you know that they don't have a view of the big picture. And in an SAP supply chain optimization you can't work in silos.

Second: "30% inventory reduction is not always a good thing". If they come in, telling you that you will recoup the investment in the project with an inventory reduction, ask them what inventory they talk about. Finished Goods? so that we can't ship or sell? Raw materials? So that we can't start production? WIP? So our production lines starve?

A blind reduction of inventories (and it is a blind suggestion because the consultancy can not possibly know your situation at that point in time) can backfire in the most devastating way. In supply chain optimization, it's all about having the right product in the right quantity at the right time in the right place. And that sometimes requires an increase of inventory.

Flow benchmarking in Factory Physics is a great way (one way out of several others) to determine the appropriate level of inventories (either as a total or broken down into finished goods, WIP and raw materials) but how many SAP consultants can tell you how that works?

Third: "Don't ever pay for an assessment!" One of the greatest scams ever is when you have to pay for someone figuring out how best they can position themselves to define a long term project with you.

If they want to see how they can help, let them take a look. If they come up with a convincable, sensable proposal then go for it. But how do you know that they are able to do that? And why would you take that risk? Let them come in and show you what they will do for you. As crazy as it sounds; i have seen SAP Optimizers who actually don't care what's in it for the customer but rather what's in it for them. No kidding. They actually think that's how it works. Must be a cultural thing!? If they recommend the book "who moved my cheese", you know that you are dealing with people who would be really good running a Kindergarden rather than optimizing your supply chain (but they might be funny and entertaining on the project).

Fourth: "a policy is a policy is a policy" In my personal opinion a supply chain optimization can only work when your buyers, schedulers and planners fully understand how to continuously and sustainably adjust the settings that drive optimized inventory levels and effective, automated strategies. A policy is what helps your user to do that. Your consultant should know what a policy is (at the least) and know how to set it up.

If your optimization partner uses some LIS transactions and key figures to show you what could be wrong, they give you a one-time fix and not a strategy for continuous improvement. Knowing that a certain item has a high dead stock is interesting, but how does that help you? They give you a "top ten hitlist of high dead stock items" and tell you to reduce the inventory. That's not an optimization. That's "hitlisting"!

So how do I get the dead stock down? And how can I avoid build-up of dead stock on other items? ...in an automated fashion without having to go through every item manually?

The answer is segmentation, classification and policy setting. If they pitch an inventory reduction and don't ever talk about policies... watch out!

The entire SAP supply chain is driven by policies which optimize and automate. A good consultant knows that and can utilize and convey their principles so that your users apply them effectively. A bad one gives you "Top Tens" and "One Time Fixes"

... more in the next blog

Too vague in my mind. And they're all selling tools... which are supposed to get you sign off on an optimization project that might cost you a lot of money without getting much, or anything out of it.

I truly do believe you should constantly improve and optimize your SAP supply chain but beware of the Sharlatans and "thought leading" experts who do a good talk but never show up when the rubber hits the road.

Here are the first four of ten bits, I think you should watch out for when the people who halfheartedly reveal all the opportunities and promise ongoing value, show up at your door knocking.

First: "only the very best advisors will do!" Most SAP consultants get away with not knowing much during the implementation. As long as they know a little bit more than the user (who, at that time usually knows only little or nothing about SAP), they look credible and knowledgeable. But once your buyers and planners were exposed to the workings of the system for years and are experiencing severe pain and developed their own work-arounds - it will take a very, very experienced and solution oriented consultant who is a top notch communicator to get your team back on track.

Be very careful and get to know the people who will perform the actual work with your team and don't let the consulting company fool you with their best few during the assessment. Very often the consulting company comes in with a "thought leader" who speaks big words and does his 'Spiel', only to leave you with a team that is inexperienced and overwhelmed with the task at hand. It also does not take a horde of consultants to do the job right. If they give you one for Purchasing and another one for Forecasting, you know that they don't have a view of the big picture. And in an SAP supply chain optimization you can't work in silos.

Second: "30% inventory reduction is not always a good thing". If they come in, telling you that you will recoup the investment in the project with an inventory reduction, ask them what inventory they talk about. Finished Goods? so that we can't ship or sell? Raw materials? So that we can't start production? WIP? So our production lines starve?

A blind reduction of inventories (and it is a blind suggestion because the consultancy can not possibly know your situation at that point in time) can backfire in the most devastating way. In supply chain optimization, it's all about having the right product in the right quantity at the right time in the right place. And that sometimes requires an increase of inventory.

Flow benchmarking in Factory Physics is a great way (one way out of several others) to determine the appropriate level of inventories (either as a total or broken down into finished goods, WIP and raw materials) but how many SAP consultants can tell you how that works?

Third: "Don't ever pay for an assessment!" One of the greatest scams ever is when you have to pay for someone figuring out how best they can position themselves to define a long term project with you.

If they want to see how they can help, let them take a look. If they come up with a convincable, sensable proposal then go for it. But how do you know that they are able to do that? And why would you take that risk? Let them come in and show you what they will do for you. As crazy as it sounds; i have seen SAP Optimizers who actually don't care what's in it for the customer but rather what's in it for them. No kidding. They actually think that's how it works. Must be a cultural thing!? If they recommend the book "who moved my cheese", you know that you are dealing with people who would be really good running a Kindergarden rather than optimizing your supply chain (but they might be funny and entertaining on the project).

Fourth: "a policy is a policy is a policy" In my personal opinion a supply chain optimization can only work when your buyers, schedulers and planners fully understand how to continuously and sustainably adjust the settings that drive optimized inventory levels and effective, automated strategies. A policy is what helps your user to do that. Your consultant should know what a policy is (at the least) and know how to set it up.

If your optimization partner uses some LIS transactions and key figures to show you what could be wrong, they give you a one-time fix and not a strategy for continuous improvement. Knowing that a certain item has a high dead stock is interesting, but how does that help you? They give you a "top ten hitlist of high dead stock items" and tell you to reduce the inventory. That's not an optimization. That's "hitlisting"!

So how do I get the dead stock down? And how can I avoid build-up of dead stock on other items? ...in an automated fashion without having to go through every item manually?

The answer is segmentation, classification and policy setting. If they pitch an inventory reduction and don't ever talk about policies... watch out!

The entire SAP supply chain is driven by policies which optimize and automate. A good consultant knows that and can utilize and convey their principles so that your users apply them effectively. A bad one gives you "Top Tens" and "One Time Fixes"

... more in the next blog

Wednesday, September 19, 2012

Inventory Analysis with the LIS. Really?

...as you probably know, SAP has provided so called 'Information Systems' as part of their software offering since the 90's. There is a Sales Information System, a Purchasing Information System, a Shop Floor Information System and many more. Each one of those has Info Structures which can be configured to collect data resulting from daily transactions. A user may then call up transaction codes which display the data through key figures and characteristics associated with the specific info structures.

The Logistics Information System, or short 'LIS', is one of these reporting systems and was mainly meant to be used for inventory analysis.

One of the problems with the LIS is that it is very rigid. There are a number of info structures provided and with those a number of key figures. And that is it. Unless you want to configure your own info structures and key figures. And that, with all due respect, is a hell of an effort. And once you set it up, there is no way you can change it again. To expect a user to maintain all of this, goes above and beyond what one can ask a buyer or planner to do. It requires a lot of technical knowledge and many, many hours of maintenance which, in the end, might be resulting in rarely used reports.

No wonder SAP stopped supporting the LIS and provided the Business Information Warehouse. But BI requires a lot of setup too and has some shortcomings as well - in my personal opinion. A major one, I think, is the fact that a data extract is generated and that means everything you see is at least one day old.

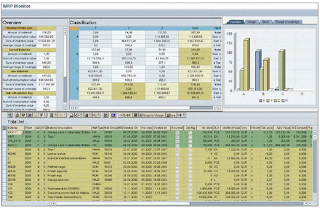

So what can you do? A very good option to do Inventory Analysis is by use of SAP Consulting's Add-On tools. There is a an MRP Monitor which allows you to perform an ABC, XYZ, LMN and EFG analysis (and much more...), which is very helpful to classify your materials for the optimum replenishment or planning policy and is neither available in standard SAP nor in the LIS (short of a very rudimentary ABC analysis).

fig.1 - ABC Analysis with the MRP Monitor

SAP Consulting offers also an Inventory Cockpit which allows you to call up reports made up of any key figures imaginable and uses the previously mentioned analysis.

fig.2 - Inventory Cockpit

fig.3 - result of the Inventory Analysis

fig.4 - more results

fig.5 - hitlist for important results

These Monitors use as a starting point the result of a 'Material Document Aggregation' that gives you utmost flexibility in filling a data table with the information you need and want. (In the LIS you can not exclude transfer postings (and much more...) from the data basis for your analysis.) Following some selection criteria that may be employed for the building of your analysis basis:

fig.6 - various, flexible selection criteria for the building of the analysis basis

There are more add-on tools available from SAP Consulting and these are all developed within the SAP namespace and therefore inside standard SAP. Marc Hoppe, the driving force behind these developments, writes about these in his books available through SAP PRESS.

There is yet another possibility that I consider very, very helpful if you want to perform an effective inventory analysis: It is using the Spreadsheet Server for SAP , QueryExchange and SmartPak offered by Global Software Inc. These are tools that you install on your laptop in Excel. The Spreadsheet Server allows you to formulate any query (KPI) you need and then goes off and pulls the relevant data out of SAP and displays it in Excel. What is important to note here is, that this does not create a a data extract (which then contains outdated information) but rather pulls the data right from the SAP table and uses an Excel formula to produce the up-to-date result.

It is a beautiful tool which practically lets you put together ANY report, KPI or query you desire, without limitations and with utmost accuracy and currency of information. Global Software's SmartPak offers you many pre-designed and pre-configured KPI's and Queries for Inventory Analysis and the graphics you can generate make the LIS graphics look like they were developed in ancient times (which, by the way, they were!)

I know that there are still consultants out there promoting the LIS - there are even consulting companies that built an entire methodology around the LIS - but don't get fooled; after they show your buyers and planners the "beautiful graphs and reports" from the early 90's and they teach them how to do a Dual Classification that looks like it should have been performed in the 80s, or a Dead Stock Analysis that runs for days - they will leave you with little or nothing that will help to determine replenishment or planning policies to optimize your safety stocks, lot sizes or inventory levels.

I am not saying you should not use the LIS anymore (...SAP does) but to spend money on a project to educate your busy users about how to use tools from the last century that are unsupported and don't really provide you with any value is not a good idea.

Subscribe to:

Comments (Atom)