Part 4 of the series addresses our ERP value stream mapping

techniques. With it we go beyond traditional value stream mapping, in that we

combine the material and information flows with specific settings we have to

configure in the ERP system so that it can support the flow we intend to obtain.

Since we often implement or optimize SAP ERP systems, I’d like to demonstrate

SAP value stream mapping here.

Value stream mapping, also known as "material- and

information-flow mapping", is a lean-management method for analyzing the

current state and designing a future state for the series of events that take a

product or service from the beginning of the specific process, until it reaches

the customer. A value stream map is a visual tool, that displays all critical

steps in a specific process, and easily quantifies the time and volume taken at

each stage. Value stream maps show the flow of both materials and information,

as they progress through the process. The difference between a value stream and

a value chain, is that a value stream focuses only on areas of a firm, that add

value to a product or service, whereas a value chain refers to all the

activities within a company.

SAP value stream mapping follows the same principles and

conventions that traditional value stream mapping does. Additionally, it adds SAP

specific data and settings. On an SAP value stream map you can document lot

sizing procedures and MRP type from the material master, work center category

and capacity related information from work centers, identify production versions

and routings to be used, define operation data from the routing with its cycle

times, and much, much more. A finished SAP value stream map can serve as a

complete documentation for a system architect, to set up all the functions,

features and customizing settings, in order to run the value stream

repetitively and effectively with SAP.

Additionally, to traditional value stream mapping, SAP value

stream mapping adds pragmatism to the design process and allows for the

immediate realization of the theoretical design.

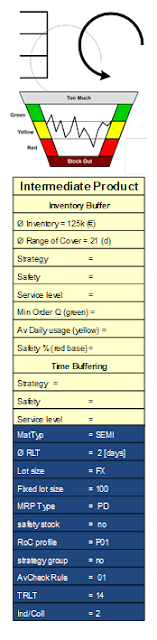

First you design the inventory points. These also serve as

de-coupling points as we will see later. An inventory point is defined in SAP

as a material master record. Without a material master record, you cannot post

a goods receipt of material into stock, and therefore, without a material

master in SAP, there is no inventory in SAP. A stock or inventory point in a

value stream map, is identified with a triangle and a capital I in it. Here we

add two boxes with data to the triangle, to maintain SAP specific inventory and

master data.

But inventory points must not be traditional stock alone. It

can also be a supermarket, as used in lean projects. If the flow is set up as a

self-organizing system, as in the case of Kanban or conwip, then we need a

supermarket, from which an order can pull. Notice the icon for supermarket is a

different one than the traditional stock point. However, the boxes below are

the same. Except that here, you may maintain control cycle data additionally to

the material master data.

Then we’ll design the material flow along work centers or

machines. Notice that the flow happens between two inventory points. Eventually

this flow will be described by a routing and then used in a production order.

From upstream, the left side of the flow, raw materials or semi-finished

product is issued and consumed to the order, and the downstream inventory point

will receive the finished product from the order. Along the routing there are

work centers and the activities, or operations which are executed on those work

centers.

The work center box contains a description of the work

center, and the work center’s SAP identification code. The blue box underneath

the identification code contains performance data of the work center. Then

there are the work center specific data settings like the work center category,

standard value key, and the scheduling formulas, amongst other things, in the

grey box. Lastly, you can identify what type of capacity may be used on that

specific work center. Is it a labor capacity? A machine capacity? Or both. The

capacity itself then, is also described by the respective data box.

Finally, we can also add the information flow to the map. All

the planning, scheduling and monitoring activities are defined there.

These SAP value stream maps can become quite elaborate and

detailed and therefore require a lot of effort to put together. We typically

plot them on big posters, hang them up on the wall in the war room and go

through various iterations as a team. The results are very rewarding in the

long run, as you can readily pinpoint inefficiencies and device some strategies

to improve all in one place.

Like mentioned before, if you put the work and focus into developing the SAP VSM, you’ll be compensated with a complete system documentation and a very solid basis for continuous improvements.

Getting Value and Results out of an ERP 1

Getting Value and Results out of an ERP 2

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.